High-Performance Dynamic Pouch Checkweigher System for Food

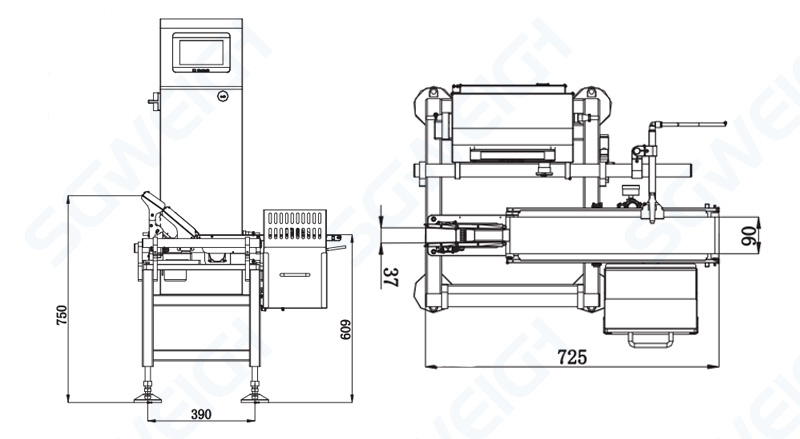

Parameter

This dynamic pouch checkweigher system uses a high-speed dynamic weighing algorithm to ensure that each product meets the specified weight requirements. Our inspection scales are able to detect overweight, underweight, insufficient quantity and other discrepancies. Our checkweigher system for food focus on accuracy, reliability and ease of use. The modular design and user-friendly design enable it to conveniently meet the various needs of different users.

| Type | SG-1X |

| Weighing Range | 1-50g |

| Limited of product | L: 180 W: 40 H: 2-20mm |

Accuracy |

±0.01g Depends on product |

| Division Scale | 0.01g |

| Belt Speed | 70 pcs/min |

| Max Speed | 100 pcs/min |

| Belt Width | 100mm |

| Machine Weight | 50kg |

| Power Supply | AC 110/220V ±10% 50HZ |

| Power | 100W |

| Main Material | SU304 stainless steel |

Balance grade Checkweigher Details

advantages

1. The open stainless steel frame provides easy access for thorough cleaning. The conveyor can be removed without tools, simplifying the cleaning procedure and reducing cleaning time. The memory card can store up to 100 operating parameters to minimize operator errors and reduce production downtime.

2. Bright and clear touch screen text facilitates error-free production control for maximum weighing performance.

3. Integration with upstream and downstream equipment centrally manages system data to optimize production line productivity.

4. Corrective control signals from the checkweigher system for food to the upstream auger filler increase productivity.

5. Checkweigher system for food provide additional quality control in a space-saving system.

Application

Dynamic Pouch Checkweigher Systems are widely used in many industries such as electronic hardware, pharmaceuticals, food, chemicals, beverages, health products, etc. For example, it can be used in the food industry to check the weight of bread, cakes, ham, instant noodles, frozen foods, food additives, preservatives, etc., as well as the weight of packaged products such as bags, pouches, boxes, jars, cans, cartons, etc.

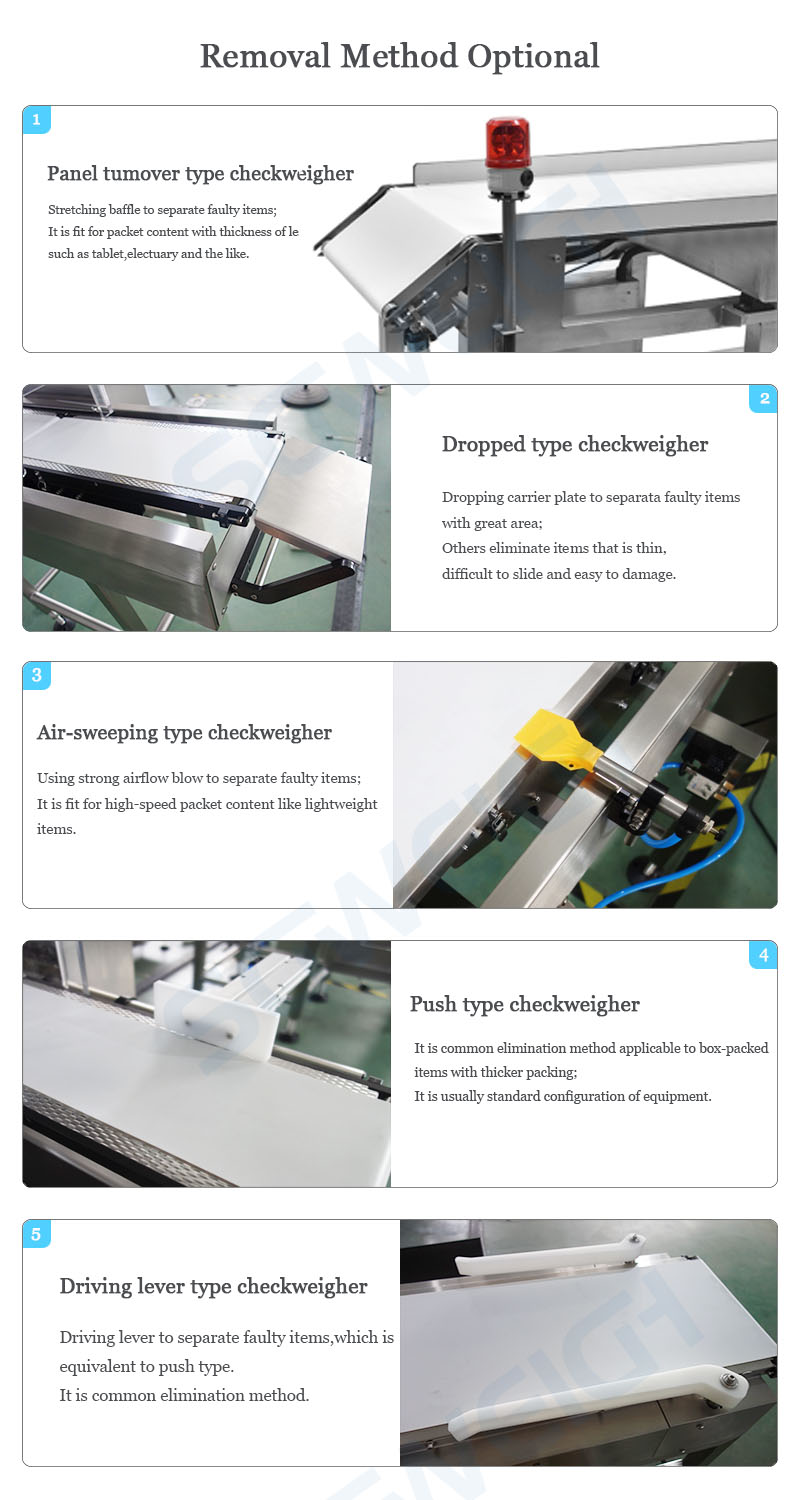

Customization Service

According to the user's assembly line and equipment application space, Shanghai Shigan provides customized services to ensure that the automatic checkweigher machine meets the actual production needs. The rejection methods include alarm prompts, lever rejection, push rod rejection, air blowing rejection and other methods. Different weighing and rejection methods are used according to the size and properties of the product.

Why choose us?

1. Competitive price. As an original manufacturer, we have our own modern workshop processing facilities, we can control good quality and cost by ourselves.

2. Prompt response. Well-trained professional sales team, working around the clock, responds to inquiries and questions within 24 hours.

3. On-time delivery. The ordered products are always delivered on time, which not only helps to save time but also helps our customers save costs. Timely delivery enables our customers to check the products before proper use. We also value our punctuality and provide trouble-free products to our customers.

4. Honesty and professional marketing policy. We always have your back. We are committed to providing the best possible service to our customers with complete honesty. Professionalism, so that our customers are completely satisfied.

5. Low maintenance. The products delivered according to customer requirements are not only of good quality but also of low maintenance cost.

6. Storage of parts and accessories. We have sufficient stock of parts and accessories for each machine.

7. Flexible customized ODM capabilities and 7*24 hours aging test before shipment.

8.Warranty scope: 1 year warranty, lifetime maintenance.