Shanghai Shigan 2024 ACHEMA Biochemical Technology Exhibition in Germany View

Shanghai Shigan successfully participated in the Germany 2024 ACHEMA Biochemical Technology Exhibitiono and continued to promote internationalization.

May 15th, Shigan Invites You to Attend The 90th API China2024 in Shanghai

Shanghai Shigan Industrial Co., Ltd. will participate in the 90th China International Pharmaceutical API Fair in Shanghai from May 15 to 17, 2024, displaying its professional autmatic checkweighers, capsule and tablet checkweighers, weight sorting machines, digital metal detectors, capsule tabelt metal detectors, checkweigher with metal detector combo, weighing labeling machines, etc. This exhibition will bring together domestic and foreign companies and experts in the pharmaceutical industry. Shanghai Shigan looks forward to communicating and interacting with you.

Shipment Notice: 21 Automatic Checkweighers for Indsutrial Companies

Today is a live photo of 21 automatic checkweigherss purchased by an industrial company on our company's website for shipment.

2023 Propak International Packaging Exhibition - Exciting Review

Shanghai Shigan Officially Resumes Work From Today!

Shanghai Shigan Spring Festival Holiday Notice

We would like to sincerely thank you for your support and cooperation over the past year. During the Spring Festival, as the most important traditional festival in China, we are pleased to inform you that we will have a short period of rest and celebration. In order to maintain smooth communication with overseas customers and ensure business continuity.

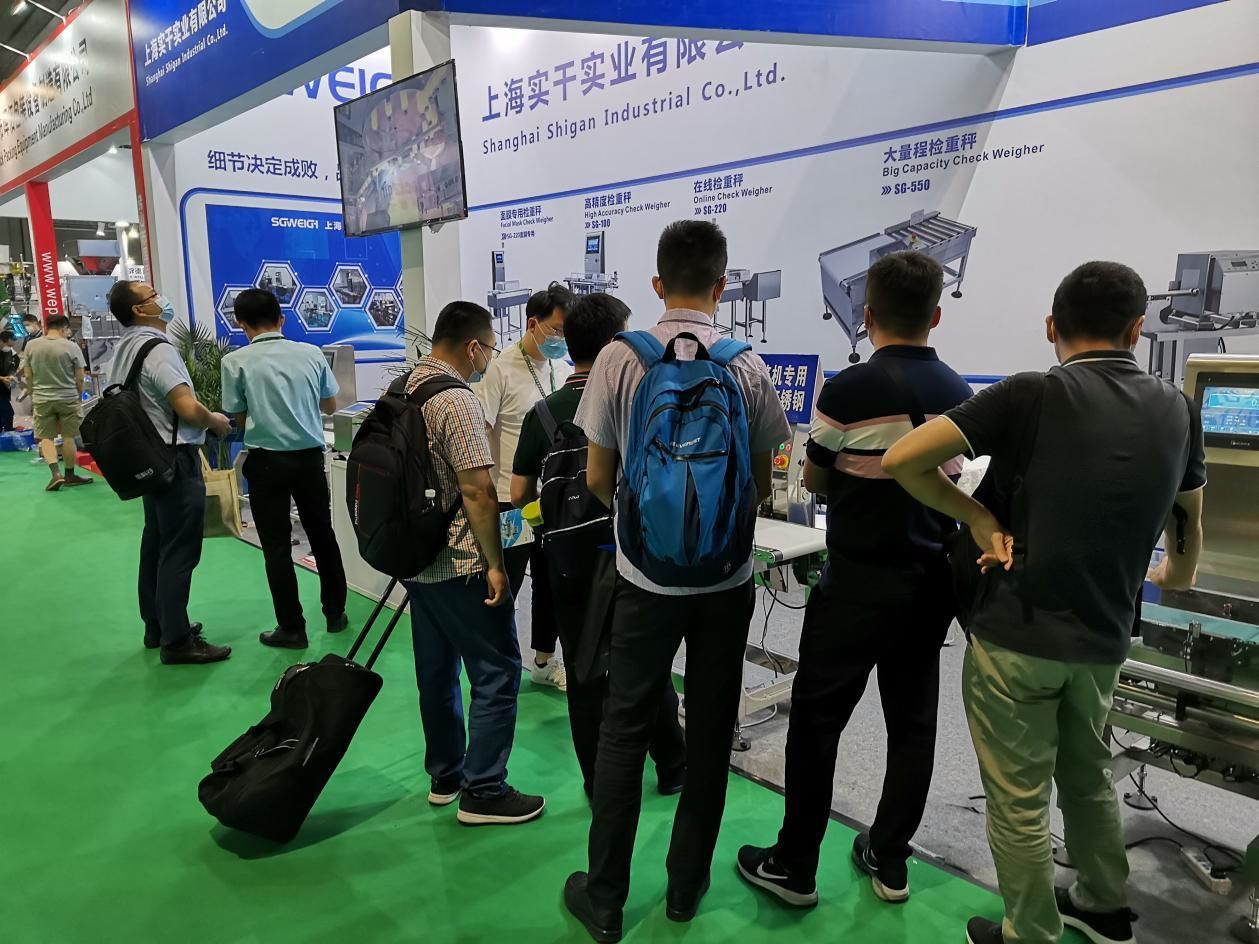

Shigan is in the 2023 China International Pharmaceutical Machinery Expo

Recently, Shanghai Shigan participated in the highly anticipated 2023 China International Pharmaceutical Machinery Expo.